Manufacturing Technology Blog is one of the oldest blogs in its domain focused primarily on metal casting and manufacturing techniques.

Challenges to the US Metal Casting Industry

However, today the US metal casting industry is facing many challenges as never before. The industry is facing the most intense global competition in its history and is severely affected by the increasing costs associated with regulations and other actions by the government, energy prices and health care.

Some of the major challenges to the US metal casting industry are -

Economic Slowdown - Slowdown in economy has resulted in slowest manufacturing recovery in decades. This recession has caused significant job losses and numerous foundry closures.

Foreign Competition - Most of the competitors to the US metal casting industry are free from complex regulations, high labor costs, and enjoy subsidies and government trade protections.

Government Regulations – Several government regulations are badly affecting the US metal casting industry. The most immediate and threatening regulation at this time is EPA's Iron and Steel Foundry MACT. This regulation is expected to be more onerous, expensive and damaging to the future of American metal casting industry.

Energy – The US industry is facing tough challenges with rising energy costs. The industry needs government support for improved efficiency, infrastructure and investments in new technologies.

World Leaders in Casting Production

According to the report, China is way ahead in the race with a reported production of 28.1 million tons in 2006. The country Chinaproduces more castings than the combined production of second through fourtChinah top producing countries. However, China is not the only country that is experiencing growth. 8 out of the top ten couChinantries showed increase in production, of which Japan and India showed a higher growth percentage than China.

According the census, the top ten casting producing nations in 2006 are given below -

China

The gap between China and other countries is increasing. With an increase of 15% over the previous year, the country now accounts for around 1/3rd of the total global production. In 2006, China's total reported production was 28,094,168 tons of metal castings.

United States

In 2006, the metal casting production of United States decreased to 12,454,739 metric tons, showing a decrease of 3.4% over the previous year. It was the first time in last four years that the country's production has not grown.

Japan

Japan showed an increase of 19.1% to stay ahead the fast growing metal casting industry of India. The country's reported production of 7.9 million tons of castings was boosted with an increase of 1.12 million-tons in the production of magnesium and aluminum castings.

India

In 2006, India's production grew by 17.5% to reach 7,179,300 tons of castings. Since 2002, the country's production has more than doubled. During the same year, India surpassed the United States in the production of gray irons.

Germany

ChinaGermany's metal casting production increased by 7.3% in 2006 to reach 5,480,900 tons. The country continues to produce more per plant than other top-10 casting manufacturing nations.

Brazil

After fast growth in 2003 and 2004, Brazil's pace is now steadying in the production of metal castings. In 2006, Brazil's production reached 3,087,045 tons, showing an increase of 4% over the previous year.

Italy

In 2006, Italy's production reached to 2,637,400 tons of castings, showing an increase of 3.8% over the previous year. The country was among one of the top four aluminum casting manufacturing countries in 2006 with a production of 900,000 tons.

France

In 2006, France's production grew by 1.7% to reach 2,381,241 tons. With a slowing automotive market, the nonferrous casting sector suffered a negative growth of 7.5%.

Korea

Metal casting production in Korea grew to almost 2 million tons in 2006, showing an increase of 3.6% over the previous year. It is the eighth consecutive groChinawth year for Korea.

Mexico

Among the top-10 metal casting producing countries, Mexico comes at 10th position with a reported production of 1,675,212 tons. During the year, the country's production decreased by around 6.3% over 2005 and it was the second consecutive year that the country has witnessed a decrease in the number of castings produced.

An Introduction to the Casting Molds

Metal casting is generally a manufacturing process wherein a liquid material is emptied into a mold, which comprises a hollow opening of the desired form or shape and is then allowed to solidify. This solidified casting is then removed and broken out so as to complete the procedure.

Metal casting is generally a manufacturing process wherein a liquid material is emptied into a mold, which comprises a hollow opening of the desired form or shape and is then allowed to solidify. This solidified casting is then removed and broken out so as to complete the procedure.While sand is used as the primary mold material, there is a metal that is used as the mold. Typically, a cast meehanite or iron is used as the mold material and sand is used to make the objects. The cavity surface is usually covered with a thin layer of material (either sodium silicate or clay), which is heat resistant.

Usually the casting molds are pre-heated to a temperature of about 3920 F before the metal is pored into the cavity. The design of cavity for these casting molds does not works on the same principle of shrinkage like in sand casting molds. This is due to the fact that casting molds heat up and enlarge during the pouring process and hence the cavity does not require to be expanded as in the case of sand castings. However, care should be taken so as to ensure a right balance as people may use an external source of water for cooling or they may also opt for appropriate radiation techniques.

Types

Casting molds can be broadly categorized into following four types -

- Permanent Casting Molds

- Slush Casting Molds

- Corthias Casting Molds

- Vacuum Permanent Casting Molds

Permanent Casting Molds

Permanent casting molds offer the benefit of lower cost of production for producing a particular part or component. However these molds are not as flexible as sand castings that can be used in a variety of designs and metal patterns.

In the case, there is a production run of more than 1000 components, a permanent casting mold may produce components at a much lower price in comparison to sand casting. In addition, the break even point also depends on the density of the component. Permanent casting molds are preferred over other types of molds for designing highly complicated parts. Typically the part size would be around 50g to 70 kg and the basic materials used are medium and small parts, which are fabricated from aluminum, magnesium, brass and their alloys.

Slush Casting Molds

These types of molds can be defined as a special kind of permanent casting molds wherein the molten metal is not allowed to harden completely. When the desired wall thickness is attained, the still not hardened molten metal is poured out. Slush casting molds are generally used to design void ornamental objects, such as lamps, candlesticks and statues.

Corthias Casting Molds

This is a kind of permanent casting mold wherein a plunger is used for packing the molted metal through the spure hole. The process permits thinner walls and to produce greater details.

Vacuum Permanent Casting Molds

This is another variant of permanent casting molds that is similar to low pressure permanent casting molds. However, in this case, vacuum is used instead of pressure. As with other low pressure casting molds, this type of mold can be used to produce thin wall castings. In addition, the results are good, as there are no risers used.

Major Cast Metals – Characteristics & Applications

Grey Iron

- Use – 54%

- Characteristics – Heat resistance, damping, economical, low shrinkage and high fluidity.

- Applications - Automobile cylinder block, clutch plate, brake drum, housings and machine tool beds.

Ductile Iron

- Use – 54%

- Characteristics – Strength, wear & shock resistance, machinability and dimensional stability.

- Applications - Crank shafts, cam shafts, valves, brackets, rollers and differential housing.

Aluminum

- Use – 12%

- Characteristics – Strength to weight ration & corrosion resistance.

- Applications – Oil & fuel pumps, automobile pistons, clutch housings and connecting rods.

Steel

- Use – 9%

- Characteristics – Machinability, weldability and strength.

- Applications – Machine parts, valves and gears.

Copper Base

- Use – 2%

- Characteristics – Corrosion resistance and high ductility.

- Applications – Valves, marine impellers and hydraulic pump parts.

Important Rules to Make Good Castings

In the recent few years, we have witnessed a considerable improvement in our knowledge of metal casting methods and techniques. With this enhanced understanding, the list of requirements has been consistently corrected as they have become known. Industry experts have identified several rules and practices, which incorporate the latest technology to manufacture quality castings.

The ten rules that have been identified are proposed as essential, but not, of course, adequate. Manufacturers should follow these rules along with the conventional technical specifications, including type of alloys, strength and traceability via quality standards, and other traditional foundry control measures, such as casting temperature, etc.

Though these rules have not been yet tested on all types of cast materials, there are reasons, which suggest that these rules have general validity and are suitable for all types of metals and alloys. The metals and alloys include those based on zinc, aluminum, cast irons, magnesium, steel, air- and vacuum-cast nickel, titanium and cobalt. In spite of all this, experts believe that these rules will probably benefit all metal casting applications, while some applications will be benefited more, others will be less affected.

Formulated to assist the casting manufacturers and designers, these rules are expected to speed up the process of producing the quality castings right the first time and in the significant reduction of scrap when the casting goes into production. Thus, these rules are expected to help the metal casting industry to raise its quality standards without any considerable increase in costs.

While on the other hand, these rules constitute a draft process, which the metal casting buyers may demand if they wish to make sure that they are buying the best possible casting quality. If the buyers ask their casting sources to follow these casting rules, the reliability and quality of castings would be better than what could be achieved by any quality control casting practice.

Rules -

Provide a Good Quality Melt

Avoid Liquid Front Damage

Avoid Arrest of the Liquid Front

Avoid Bubble Damage

Avoid Core Blows

Avoid Shrinkage Damage

Avoid Convection Damage

Plan Segregation Distribution

Control Residual Stress

Provide Location Points

Learn the Basics of Metal Casting Crucibles

Crucibles Shapes:

Metal casting crucibles come in two shapes – “A” shape and Bilge shape.

Bilge shaped crucibles have the shape of a barrel. The region in the middle part of the crucible is known as bilge, which is the widest part of the crucible and has the maximum diameter. Bilge has greater diameter than the top of the crucible. According to a thumb rule, the # of a bilge crucible reflects the number of pounds of aluminum, which it can hold. In the case of brass and bronze, three times of the # can be held. For example, a # 5 bilge crucible can hold around 5 pounds of aluminum and around 15 pounds of brass. This thumb rule applies only to bilge shaped crucibles.

“A” shaped crucibles have a narrow bottom and a wider top. This types of crucibles have straight sides, which are bent outwards and the diameter increases from the bottom to the top. “A” shaped crucibles are easier to design than bilge ones and hence have lower cost.

Both Bilge as well as “A” shape crucibles can be manufactured in clay graphite and silicon carbide.

Properties of Crucibles:

A crucible should be designed in a way so that it can handle the extremely high temperatures of the molten metal. For this, the crucible should be made of a material, which has a melting point more than that of the material to be melted in the crucible. In addition, the crucible material must have superior strength even in white hot state.

For melting metals, such as aluminum and zinc, a home made steel crucible can be used. However, in this case, the interior surface of the crucible undergoes scaling or flaking, which may pollute the molten metal. It also quickly decreases the thickness of the crucible walls. To solve this problem, a coating of marcote-7 is applied to the inner surface of the steel crucible. The use of steel crucibles is allowed if the contamination due to scales is not serious.

Materials Used:

To design a crucible, the usual refractory materials (such as carbon bonded silicon carbide and clay graphite) can sustain the extremely high temperatures in a foundry. Moreover, silicon carbide is a highly durable material.

Some types of the clay graphite crucibles can be used up to a temperature of 2750 degrees Fahrenheit. Some “A” shape crucibles can be used up to a temperature of 2000 degrees Fahrenheit. These crucibles can be designed to melt silver, gold, bronze, brass, aluminum and zinc alloys.

“A” shaped crucibles have a rough surface finish and have dents along the rims. However, this roughness and dents does not affect the performance of these crucibles.

For proper handling of crucibles, adequately fitted tongs should be used. Poorly designed tongs may result in the damage or the total failure of the crucible. A disk of cardboard or a Plumbago coating should be placed in between the base of the furnace and the crucible.

Recycled Foundry Sand – Uses & Applications

Sand used at foundries is of superior quality, as companies adopt stringent physical and chemical tests to ensure production of defect free castings. Foundries make considerable investments for the quality control of their sand systems with rigorous testing done to ensure consistency.

Though there are several methods of casting, including - die casting, investment casting, and permanent mold casting, sand casting is by far the most preferred casting technique. There are 2 different methods of using sand in metal casting industry -

- As a molding material that forms the external shape of the cast component

- As a core that forms the internal void spaces in products such as engine blocks.

Types of Foundry Sand Suitable for Recycling

Generally two types of binders are used in metal casting industry -

- Clay bonded systems (green sand)

- Chemically bonded systems (resin sands)

Both these types of sand are suitable for recycling and beneficial reuse, however they have different physical and environmental properties.

Uses of Recycled Foundry Sand

Sand from ferrous and aluminum foundries comprise more than 90 % of available sand and is usually best suitable for recycling. Ferrous and aluminum foundries are generally big in size in comparison to other nonferrous foundries and because of the nature of their production, they have more uniform sand streams. This type of sand has a history of uses in different types of construction applications.

Some innovative foundries are finding ways to recycle their used sand. Some other type of non-ferrous sand, or mixed sand streams can be recycled if they fulfill the environmental testing requirements of the regulatory agencies and the required performance standards of the industry.

As with other materials, transportation costs are usually the highest cost factor in the recycling of foundry sand. Considering the cost factor, the best option for the recycling of foundry sand will typically match the volume and characteristics of the foundry sand with businesses and construction projects in nearby areas.

Given below are some of the markets that have the potential to absorb recycled foundry sand from different types of foundries -

- Construction Projects

- Cement Kiln Feedstock

- Flowable Fill

- Manufactured Soils

- Hot Mix Asphalt

- Ready Mix Concrete

- Precast Concrete Products

- Bricks and Pavers

- Grouts and Mortars

- Landill Daily Cover

- Landfill Construction Material

Copper – An Introduction to the Versatile Metal

For around 5 millennia, copper was the only metal known to man, and hence has all the possible metal applications. It was the 1st metal mined and produced by man, and has great significance in older days because of its huge availability. Moreover, copper metal was suitable for crafting weapons, tools, art objects and jewelry.

The wide uses and applications of copper metal over the years of its discovery are well documented. Today, this versatile metal can be seen in objects, as familiar as coins in our pocket, the Statue of Liberty and plumbing products in more than 80 % of all households in the United States.

The metal is invaluable to mankind in a wide array of applications that range from production of alloys to power transmission, to micro-electronics. Each of the thousands of uses of the metal employ a combination of characteristics to help ensure material, which is perfect for the purpose. Good thermal and electrical conductivity combined with strength, ductility and excellent corrosion resistance, are some of properties of this metal that make copper a valuable metal for a range of applications.

The metal is generally found as the multivalent cation, Cu (II), and less frequently as the monovalent ion, Cu (I).

Mining of Copper

About two hundred years ago the UK was an important source of copper for the world and there were mines in Wales and Cornwall. These mines have now closed and today the largest copper mines are located in Chile and North America, which generate several thousands of tonnes of copper every year. The main ores of copper are:

Chalcopyrite

Bornite

Malachite.

These ores are extracted either using traditional mining techniques or through leaching. The pure metal is then retrieved using physical and chemical process.

Recycling

Copper metal is very well suited to recycling and can be remelted again and again with no loss of characteristics. For instance, old copper plumbing taps, pipes, and car radiators are important sources of recycled copper. All these products can be melted down and crafted into new products. In the future, even a tiny amount of copper in the mobile phone will be worth retrieving.

Did you know that copper

Is found everywhere in the Earths' crust.

Is vital to humans. Adults require 2-3 mg in their diet daily.

Is critical to the metabolism of all living organisms.

Provides superior corrosion resistance, excellent electrical and thermal conductivity.

Has good formability.

Is environment friendly and recyclable. More than 80% of copper every mined is still in use.

Has been used extensively in tools and jewelry over 6,000 years ago.

When alloyed with zinc, produces brass.

When alloyed with tin, produces bronze.

Aluminum : Facts Behind the Metal

Bauxite is the main mineral ore of aluminum, which is abundantly available in tropical areas, such as - Africa, the West Indies, South America and Australia. Bauxite contains all types of impurities - mainly metals, such as iron - but comprises of 45 % to 60 % aluminum oxide, or alumina.

In its metallic form, aluminum metal does not occur naturally. It occurs only in combination with other minerals in the form of oxide or silicate compounds that constitute about 8% of earth's crust.

According to estimates, about 29 million tons of aluminum is required to meet the global demand every year. Of this total 29 million tons of total aluminum, around 22 million tons is new aluminum and 7 million tons is obtained by recycling the aluminum scrap. About 25% of the total amount of aluminum used across the world is recycled material.

Fact – 50% of the aluminum cans used today in the US are recycled.

According to estimates since 1972 around 16 million tons of aluminum cans have been recycled. These 785.6 billion aluminum cans if placed end-to-end could stretch to the moon more than 249 times.

Production of Aluminum

Production of aluminum is a two stage process that comprises of various intermediate steps. In the first stage, different mechanical and chemical stages are used to purify the bauxite and recover the alumina with the help of “Bayer Process”.

Once the alumina - aluminum oxide trihydrate - is retrieved, it can be electrolytically reduced (transformed through electrochemical means) into metallic aluminum.

Some Facts -

- Aluminum can be very strong, light (less than 1/3rd of the specific gravity of copper, brass or steel), ductile, and malleable.

- The metal is an excellent conductor of heat and electricity.

- Polished aluminum has the highest reflectivity of any material - even mirror glass.

- The metal can be rolled, cast or extruded into an infinite array of shapes.

- As a packaging material, aluminum as unique barrier characteristics. It resists corrosion and can be recycled again and again, without any loss of quality or properties.

- The metal can be mixed with small, often minute, quantities of other materials, such as - copper, zinc, silicon, iron, magnesium, tin, titanium, lithium, chromium, tungsten, manganese, nickel, and others to create a variety of alloys with very different physical characteristics.

- Aluminum metal is so widely used in todays' modern world that it is very difficult to imaging a world without it. The amazing, unique properties of this fundamental metal give it an extensive array of possible applications, including - transport, packaging, electrical application, medicine, and construction of homes and furniture.

Metal Casting Applications in Japan

As like in Germany, the uses and applications of CAD solid modeling are limited in Japan. Again, as enabling technique for rapid prototyping (RP) machines, a CAD solid model should be designed before a component can be fabricated. The applications of 2-D CAD is very common in Japan.

Mostly a 2D CAD file is transformed to a 3D CAD solid model, then fabricated on an RP machine, however the additional step of designing the solid model increases the cost of the rapid prototyping component. Rapid Prototyping competes with machining for creating prototype components in Japan. In several cases, even complicated geometries can be machined as quickly as parts can be produced using rapid prototyping.

There are a large number of small machine shops in Japan, and the increasing competition in t5he industry makes machining an attractive option in comparison to RP. Low accuracy and surface roughness of components made through rapid prototyping is another drawback of this process. However, with the increasing usage of CAD solid modeling, the applications of rapid prototyping are expected to increase.

The table given below shows some of the Rapid Prototyping systems in use in Japan -

Research & Developments

R&D works for metal casting applications in Japan are mainly focused on the development of materials and software for fabrication of patterns.

Summation

In conclusion, we can say that CAD solid modeling is not used very widely in Japan. In several cases, component designs have to be transformed into solid models before fabrication by a rapid prototyping machine. This results in the increases in the price of RP components. Rapid prototyping can be compared to CNC machining in respect with cost, scheduling, and quality. Inadequate accuracy and surface finishing of parts fabricated using the RP technique are limiting their usage in Japan. Though some of the small companies are are aggressively and successfully using the RP technique for metal casting applications.

Advantages of Die Castings Over Plastic Components

A highly preferred casting method among manufacturers and designers, die casting is an efficient and economical process that offers several advantages for creating parts and components. Because of these advantages, die casting becomes an obvious choice when selecting a manufacturing process for a specific part. However, sometimes the designers must compare the benefits of die casting over other methods, such as plastic injection molding.

A major advantage of die casting over plastic components is that die casting makes stronger parts with closer tolerances, which have higher stability and durability. Die cast components are also known for their superior temperature resistance and electrical properties.

Another thing that is adding value in favor of die castings is that the continuous increase in the prices of oils is having a considerable impact on the price of plastic feed stocks used in manufacturing components. With continuously increasing crude oil prices, the prices of plastic components produced from oil feedstock are bound to increase as well.

Advantages of Die Casting

Although both die casting and plastic injection molding are high-speed manufacturing processes, die casting offers several advantages over plastic components, including-

Strength, weight and heat tolerance – These primary metal characteristics favor die castings over plastic components for a variety of applications. Die cast components are stronger than plastic injection moldings of same dimensions. In addition, the variety of choices available for zinc, aluminum and magnesium alloys allow designers to select materials, which can be used in high temperature conditions.

Dimensional Accuracy & Stability – Die casting process creates parts, which are durable and dimensionally stable, while retaining close tolerances. Plastic components are more susceptible to warping and surface sinking in regions above ribs is far more common. Several die casting alloys also offer better creep resistance.

Multiple Finishing Techniques - Die cast components can be created with smooth & textured surfaces, and can be easily plated or finished with a minimum of surface penetration. Components can be cast with lettering or ornamentation, which allows finer details and higher resistance to wear than plastic parts. In addition, as die casting creates complex shapes within closer tolerances, little or no machining is needed.

Recyclability – According to reports, more than 95% of aluminum die castings manufactured in North America are produced from post consumer recycled aluminum. As the production of recycled aluminum alloy needs less energy than producing the alloy directly from ore or other techniques, there is a significant conservation of non-renewable energy resources. More than 85% of aluminum in a car is presently reclaimed and recycled, while most of the plastic in a scrapped vehicle is considered as a fluff and is sent to waste dumps.

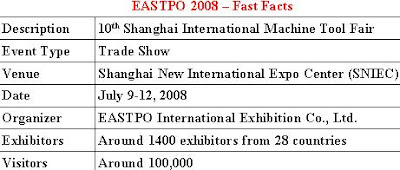

EASTPO 2008 - 10th Shanghai International Machine Tool Fair

The event, which has been successfully held for 9 years, plays a crucial role in introducing international cutting-edge technologies to China and accelerating the internationalization of Chinese machine tool manufacturers. The 2nd largest machine tool fair in China, EASTPO serves as a platform for exhibitors to show their state-of-the- art products and as window for visitors to keep abreast with the latest developments of industry. And most important of all, the event opens new perspectives on the future of industry for visitors and exhibitors alike.

Exhibitor Profile

Exhibitors from the different segments of machine tools industry participated in the event, including -

- CNC metal cutting machine

- CNC metal forming machinery

- Fabrication equipment

- Non-traditional processing machinery

- Material handling equipment

- Foundry machinery

- Heat treatment equipment

- Welding equipment

- Other related manufacturing technology and equipment

Industry Focus

General Industrial Equipment , General Mechanical Components , Manufacturing & Processing Machinery , Measurement & Analysis Instruments , Tools

Products and Services Focus

Machine Tool, Machinery, Tools

Advantage for Visitors

- Keep updated with the latest technology and productivity innovations in manufacturing

- Interact with experts from across the world who can provide solutions to your manufacturing needs and challenges

- Gain valuable knowledge and information from seminars focused on improving production efficiencies

- Meet suppliers who can help grow your business

- Get sophisticated technologies and ideas for the future

Venue

Shanghai New International Expo Center (SNIEC)

Rm1201, Greenland Business Center, 1258 Yuyuan Road, Shanghai, China-200 050

Phone: 86 - 21 - 52396593

Fax: 86 - 21 - 51010002

Website - www.en.eastpo.net/

Email - eastpo.net@gmail.com

Buying Tips - Cast Metal Components

Cast metal components are not products, which are generally bought out from market; most often they are custom made objects, designed and engineered to meet the specific requirements of a particular customer. As such, we can say that cast components high value and high volume commodity items, where price is the main buying criterion.

Cast metal components are not products, which are generally bought out from market; most often they are custom made objects, designed and engineered to meet the specific requirements of a particular customer. As such, we can say that cast components high value and high volume commodity items, where price is the main buying criterion.Cast components are considered as high-value manufacturing products, where the production facility (foundry) is an extension of the manufacturing capability of buyer that involves long-term relationships and open, on-going communication at different stages. Since these are considered as high value products, the buying criteria for cast metal components involve a fine balance of quality, cost, service and delivery.

According to experts and OEM component buyers, properly formulated buying policy is fundamental to the "best-value" procurement of cast metal products. The buying policy should specify the buyer-partnership, and is based on the following principles:

- Long-term partnerships based on shared interests and optimal value for concerned parties.

- Reliable cast component suppliers who are capable to meet the standards of production quality, supply on time, offer knowledge and expertise to facilitate component design and improvement and offer best price and value.

- Open and uninterrupted communication at different levels including executive, purchasing and technical levels to facilitate concurrent engineering/design, design for production and regular improvement.

Improve Induction Melting With Gas Diffusers

Also known as porous plugs, gas diffusers have been used for many years in ladles to enable gas purging of steel melts before streaming the metal into molds. The purging process degasses the melt and makes cleaner steel that results in a repressed scrap rate in castings.

Also known as porous plugs, gas diffusers have been used for many years in ladles to enable gas purging of steel melts before streaming the metal into molds. The purging process degasses the melt and makes cleaner steel that results in a repressed scrap rate in castings.According to experts, the proper use of gas diffusers provides a variety of benefits in induction melting. These include reduced scrap rates, more efficient melt, and a considerable improvement in furnace operational life.

For safe and effective functioning of a gas diffuser, several factors have to be taken into account. The chosen refractory material should be able to withstand penetration when in touch with liquid metals. The gas diffuser should be designed in a way so that it supplies little quantities of inert gas to the induction furnace melt in a controlled manner. The diffuser must also be compatible with the lining materials of the induction furnace. The diffuser must also be designed in a way so as to ensure easy installation, operation and long service life.

If possible, the diffuser must be fitted in the center of furnace base, or as close as possible to the center.

The furnace should have a gas supply to connect to the gas diffuser, and a there should be a proper gas-flow control arrangement. Such a system can be as simple as a pressure regulator on an argon-gas bottle with an inlet needle valve and flow meter; or as complex as a PLC package linked to a computer-controlled process control arrangement.

The induction furnace lining should be sintered before using the gas diffuser; this helps the gas to pass through the lining without disturbing it. In order to ensure proper sintering, gas diffusers should not be used early in the melting process. According to experts, best results can be obtained by bringing in the gas to the diffuser during the 3rd melt and onward.

Rapid Tooling - A Key to Production Improvement & Cost Savings

Rapid prototyping is fast emerging as a preferred manufacturing method among global manufacturers to bring products faster to the market. As a part of this process, manufacturers are using varied tooling methods to design pre-production models, limited parts of production runs, and even production quality tools of the rapid prototyping process. Die casters are using a variety of rapid tooling methods to produce pre-production models, limited runs of production parts and even production quality tools subject of running up to 100,000 parts in certain cases.

Rapid prototyping is fast emerging as a preferred manufacturing method among global manufacturers to bring products faster to the market. As a part of this process, manufacturers are using varied tooling methods to design pre-production models, limited parts of production runs, and even production quality tools of the rapid prototyping process. Die casters are using a variety of rapid tooling methods to produce pre-production models, limited runs of production parts and even production quality tools subject of running up to 100,000 parts in certain cases.It was during the year 1980, when developments in rapid prototyping started with the help of computer aided design or animation modeling software. These tools were used to convert the virtual designs into cross-sections constituting the physical dimensions of the model. The procedure can be compared to that of a topographical model where the layers represent to the elevations in the model. The virtual model is then transformed into a real design through either additive or subtractive prototyping.

Substractive prototyping is a conventional method of rapid tooling that is used create a die tool. In place of machning the steel in the tempered condition and afterwards heat treating it, pre-hardened steel used. The process helps in shortening lead time. Sophisticated cutting tools provide for machining of steels up to 40-42HRC. Die life can increase from a few thousand shots to tens of thousands, which depends on configuration of the part.

- Variety of tooling methods for unique and specific requirements

- Designs can be quickly transformed from prototype to production

- Rapid tooling cuts production time

- Possible to create complex designs

- Economical

Modern Metals – A Leading Publication for Metal fabricators, Service Centers and OEM's

A name of trust in the metal casting world, Modern Metals is a monthly publication serving the medical service centers, OEMs and fabricators. Each issue of the magazine presents the different facets of the ever changing process of a metals' journey from the mill to the ORM / end user. The non biased approach of the editorial board of the magazine presents a clear and balanced picture of the metalworking industry.

A name of trust in the metal casting world, Modern Metals is a monthly publication serving the medical service centers, OEMs and fabricators. Each issue of the magazine presents the different facets of the ever changing process of a metals' journey from the mill to the ORM / end user. The non biased approach of the editorial board of the magazine presents a clear and balanced picture of the metalworking industry.The landscape of the metals industry is shifting at a pace faster than ever. Rapidly increasing global competition, integration, distribution and new technological developments are acting as the forces of change in the industry. With constantly evolving and expanding global metal industry, Modern Metals magazine help the readers stay ahead in the business by featuring latest news and issues, metal processes, technological developments and industry trends.

Unlike other vertical or niche industry publications that tend to focus on a particular aspects or the audience within metal industry; Modern Metals magazine features articles that take readers through an ever-changing process of a metal's journey from the mill to the OEM/end-user. The publication stresses the important role that metal service centers play, along with the fabricating and forming stages.

International Journal of Metal casting – Driving the Research & Technology for the Global Metal Casting Industry...

A renowned name in the field of global metal casting industry, International Journal of Metal casting (IJMC) is a quarterly publication of the American Foundry Society (AFS). The publication keeps track of the latest news and issues, technological research and developments, happenings and events of the metal casting industry.

A renowned name in the field of global metal casting industry, International Journal of Metal casting (IJMC) is a quarterly publication of the American Foundry Society (AFS). The publication keeps track of the latest news and issues, technological research and developments, happenings and events of the metal casting industry.Paper Types:

The magazine publishes technical papers and reports in 4 extensive categories -

- Technical Papers

- Technical Development Reports

- Technical Communication

- Technical Update

Paper Review

All the papers released in the journal are sanctioned only after a rigorous peer review process. The editorial peer review board comprises 3 international metal casting groups that include -

- Academia (metal casting professors)

- Science and Research (professionals from national labs, research and scientific institutions)

- Industry (leading technical personnel from metal casting facilities)

Tool to Determine Casting Alloys & Processes

In collaboration with American Foundry Society, Product Development & Analysis LLC has developed a tool to help casting buyers and designers determine which particular alloy and casting process suits best to their specific metal casting designs. This tool is known as Casting Alloy & Process Selector (CAPS) Tool . The casting buyer is just required to enter the basic data about the metal (if available - weight, alloy, wall thickness, surface finish, production volume), and the tool will present the different casting process.

The tool gives the results on the basis of data, facts and information stored in it and provides industry averages that cannot be considered absolute. Though the tool helps the casting buyers and designers to narrow down their choices, the user should contact the manufacturer for specific as different manufacturers have different capacities

New Manufacturing Methods : Expected to Cut Down the Cost of Titanium Alloys

Ever since the introduction of titanium and its alloys in the mid of 20th century, these metals have become critical materials for uses in aerospace, energy and chemical industries. Titanium and its alloys combine properties, such as high strength-to-weight ratio, superior mechanical properties and corrosion resistance that makes them an ideal choice for a multitude of critical applications.

Ever since the introduction of titanium and its alloys in the mid of 20th century, these metals have become critical materials for uses in aerospace, energy and chemical industries. Titanium and its alloys combine properties, such as high strength-to-weight ratio, superior mechanical properties and corrosion resistance that makes them an ideal choice for a multitude of critical applications.Today, the titanium alloys are used in highly demanding applications, including the static and rotating gas turbine engine parts. Titanium alloys are also used to design some of the most critical and highly stressed civilian and military airframe components. Though highly preferred metal choice for such critical applications titanium alloys tend to be too expensive and this limits their widespread use in industrial applications.

However, improved manufacturing techniques and processes are in development stage that are expected to reduce the prohibitively high cost of titanium alloys. Oak Ridge National Laboratory and industry partners are working progressively to formulate a new and innovative non-melt consolidation process. This new technique is expected to cut down the amount of energy and cost required to produce titanium alloy parts and components by upto 50%. The process will make it viable to use titanium alloys for a multitude of engineering applications, including armor for military vehicles.

Recently, the Oak Ridge National Laboratory used new low cost titanium alloys to design a door for the Joint Light Tactical Vehicle, which is a next-generation combat vehicle. While the main purpose of the use of titanium alloy door was to reduce the weight of the vehicle, it also provided the benefit of decreasing the threat of armor – piercing rounds. Light in weight, the titanium alloy door also enhanced the functioning of door and cut down the overall weight and the fuel efficiency of vehicle, thereby making it even more beneficial for the military and industrial applications.

According to experts, the non-melt approach that comprises roll compaction for directly fabricating sheets from powder, press and sinter techniques to create exact near net shape components and extrusion, provides several benefits over conventional melt processing.

While titanium powder is used to design products in the traditional melt processing method, the powder remains in its solid form during the entire process. This saves a vast amount of energy required for processing, cuts down the amount of scrap by a great amount and allows for new alloys and engineered composites.

Though powder metallurgy has been used to design parts and components for several years, the process is generally not used to fabricate titanium products because of the high cost of traditional titanium powders. New low cost titanium powders are now allowing the researchers to formulate these technologies for titanium.

In coming years, researchers expect the introduction of lightweight corrosion-resistant titanium alloys into several other products, including automobiles that will benefit from the reduced weight and will be able to provide better fuel efficiency.

Rising Electronic Waste: Dangers & Solutions

Majority of people don't know what happens to their old electronic gadgets when they throw them out of their homes. Considering the fact that these waste electronic gadgets contain both the toxic chemicals as well as valuable metals you'd think someone would know this? As a matter of fact, however, the fate of millions of tons of e-waste produced each year is mostly unknown.

Majority of people don't know what happens to their old electronic gadgets when they throw them out of their homes. Considering the fact that these waste electronic gadgets contain both the toxic chemicals as well as valuable metals you'd think someone would know this? As a matter of fact, however, the fate of millions of tons of e-waste produced each year is mostly unknown.As the electronic products are becoming cheaper day by day, people generally prefer to replace them instead of fixing them. As a result of this, the amount of old electronics, or e-waste, such as computers, TVs and phones being discarded every year is increasing vastly and in some countries it is the fastest growing type of waste.

With electronic products rapidly becoming a part of throw away culture in several developed countries, the amount of e-waste generated has increased significantly while the solutions have often lagged far behind. Even in the European Union (EU), which has set stricter regulations, about 75% of e-waste is unaccounted for. On an estimate, of the 8.7 million tonnes of e-waste that is generated every year in EU, a vast amount of 6.6 million tonnes of waste is not recycled.

In the United States, there is very little regulation regarding e-waste. Less than 20% of e-waste is collected in the country for recycling. Among these, the recycling percentages for PCs (10 %) and TVs (14 %) are even lower. The impending shift to digital TVs in the US and in other countries will result in a vast increase in the amount of excess analogue TVs.

Even from the 20% of scrap that is collected in the United States, most is exported to the developing nations in Asia and Africa and that is a warning signal.

The vast amount of e-waste that is not recycled can be attributed to -

- Storage: Normally people used to keep their waste electronic products stored in the house for a long time and this leads to the delay these products are ultimately discarded and slims the chances they could be properly recycled.

- Landfill/Incineration: When electronic products are mixed with domestic waste, they are most likely to end up in a landfill or incinerated. Both these methods cause the toxic chemicals present in e-wastes to pollute the environment.

- Reuse and Export: Majority of the old computers and phones are traded to developing nations for reuse and recycling. Most of these are crudely recycled in e-waste scrap yards making widespread pollution.

Technology Divide

Countries like China and India have long been the destinations for dumping of e-waste by unethical traders looking to make quick bucks on e-waste from the western countries. Now even the amount of e-waste generated in these countries is growing fast. In India only 1% of e-waste is recovered for authorized recycling.

Several informal recycling yards have opened up across Asia & Africa that utilize primitive methods to recover valuable metals from scrap. These recycling plants lack in modern technology and use methods that create huge environmental pollution and health risks for the workers.

Even properly ordered and well intent shipments of computers for reprocessing are being ill-treated. According to traders in Ghana, they have to accept junk electronic products in return for a shipping container with a few working computers. The junk products and even the working computers ultimately end up dumped in Ghana, as the country has no infrastructure to recycle toxic e-waste.

Solutions

In my opinion, the problem of e-waste scrap cannot be tackled until the governments, product makers and the consumers all come together to address the issue.

It is the governments' responsibility to make tighter regulations regarding the proper use and disposal of electronic products. It is also the duty of the governments' to prevent the unauthorized export and import of e-waste in their respective countries.

The problem can be significantly reduced if the major electronics companies work to eliminate the harmful toxic chemicals from their products and improve their recycling programs. After generating great demand for their latest mobile phones, sleek laptops and making huge profits from the sale of electronic products, it becomes the moral duty of these electronics companies to take steps to reduce electronic scrap and fight pollution.

To handle the rapidly increasing amounts of e-waste, all manufacturers should offer free and convenient recycling of their goods to all their clients. Where companies are not willing to do this, strict legislation is required to ensure the safe recycling of waste recycling products.

At last, consumers can play their part in e-waste reduction and safe recycling by timely returning their used electronic products to scrap recyclers.

Reducing Zinc Contaminants is Critical to the Success of Die Castings

Manufacturers prefer zinc alloys for a variety of applications that range from small electrical connectors to automotive parts and decorative components. According to a research study, the global consumption of zinc casting alloys is more than one million metric tons.

Manufacturers prefer zinc alloys for a variety of applications that range from small electrical connectors to automotive parts and decorative components. According to a research study, the global consumption of zinc casting alloys is more than one million metric tons.Zinc alloys are used in casting applications because of their mechanical characteristics, electrical conductivity, dimensional accuracy and machinability. Functional components are manufactured keeping in mind the stable mechanical properties over the design life of part, along with good dimensional precision. Metals for decorative components are chosen depending on their ability to maintain good corrosion resistance over a variety of exposure conditions. Many castings are designed with both functional as well as decorative attributes, however these characteristics may be vitiated if the zinc alloy is contaminated. For instance, high level of lead may cause intergrannular corrosion during plating works.

The presence of tin, lead, cadmium and antimony at a level higher than the permissible limits can adversely affect the mechanical properties and corrosion resistance of zinc castings.

Both die casting manufacturers and alloy producers are agreeing on the need to improve purity levels by adopting advance processes and sophisticated technology. In recent years, however, several instances of out-of-specification imported castings have been reported. According to experts, these instances are related to the hand sorting of scrap used to produce secondary alloy. Presence of little tin and lead can have significant impact on the purity of zinc alloys.

Presence of tin and lead in zinc alloys can be attributed to several factors, including - solder leftovers and bronze bushings, which are not separated from the secondary feed. Latest technology separation, alloying and alloy analysis methods can be used to rule out the risk of contamination of ingots, however, these must be carefully followed to ensure the supply of in-specification product.

Affect of Impurities

Though tin is considered as the most harmful impurity for zinc alloys, the presence of lead, cadmium and antimony at levels higher than permissible limits can also badly affect the mechanical properties and corrosion resistance of zinc alloys. In addition, when these impurities coexist in the contaminated alloy, their effects can get compounded. These impurities act as microscopic-size cathodes, finely diffused throughout the alloy along its grain boundaries and reduce the properties of zinc alloys. The zinc alloys generally corrodes at these areas.

Quality Control Procedures

To avoid zinc contaminants and to ensure the production of successful die castings, the zinc alloy producers needs to take several steps, including -

- Use only certified special high grade zinc in their manufacturing. This eliminates the risk of lead, cadmium and tin contamination.

- Each lot of zinc and die casting alloy must be produced as per the ISO 9001:2002 documented norms and procedures, which include different assays of the molten material during pouring off of the heats.

- Track and identify the likely harmful sources of contaminant, including customer returned scrap for reclaim.

Metal Recycling – Fueling the Global Manufacturing Supply Chain

Metal recycling companies recycle more than 81.4 million tons of iron and steel, 1.8 million tons of copper, 4.5 million tons of aluminum and around 1.4 million tons of stainless steel every year.

Metal recycling companies recycle more than 81.4 million tons of iron and steel, 1.8 million tons of copper, 4.5 million tons of aluminum and around 1.4 million tons of stainless steel every year.Companies involved in metal recycling transform these otherwise wasted resources into the raw materials, which fuel the manufacturing supply chain, supporting the world economy, trade and contribute to resource sustainability.

Part of a $65 billion industry, metal recyclers process ferrous metals, such as steel and iron—the most recycled metals - recovered from scrapped cars, appliances, buildings and bridges; non-ferrous metals, such as copper, brass, bronze, aluminum, zinc, magnesium and lead that are found in various things, including building materials, to beverage containers, and in waste electronic equipment; and precious metals, such as - gold, silver and platinum, also found in electronic equipment and computers.

Metal recycling is a hi-tech industry industry that employs tens of thousands of employees to convert discarded metals into useful economic commodities.

Some of the Most Recycled Metal Products -

Metals can be recycled again and again to produce useful raw materials. Though all types of metals can be recycled, aluminum and steel are most recycled. Some of the most recycled aluminum and steel products are -

Aluminum

- Soda cans

- Appliances

- Auto parts

- Windows

- Doors

- Tin Cans

- Auto parts

- Bridge parts

- Appliances

- Torn-down buildings

Advantages of Metal Recycling

It makes sense to use recycling to convert discarded metal products into useful raw materials rather than continuously depleting the earth's natural resources. Some of the important advantages of metal recycling are -

- Less energy required to melt down a waste metal and recycle it than it does to produce new metal.

- Use of recycled metals reduces CO2 emissions and air pollution.

- Less land and water pollution.

- Decreases environmental damage caused by mining.

- Metals can be recycled over and over again.

- Metal recyclers pay you for your scrap.

11 Effective Design Tips to Improve the Performance of Your Castings

While designing castings, the most important thing to consider is the effect of shrinkage during cooling. Some other critical factors include the flow of metal and porosity.

While designing castings, the most important thing to consider is the effect of shrinkage during cooling. Some other critical factors include the flow of metal and porosity.Some general casting design rules are -

- Avoid sharp corners - they may result in hot tearing during cooling.

- Fillets should be used with care – they lead to stresses as they shrink. Radius in the range of 1/8” to 1” is acceptable.

- Use uniform cross sections – they keep the cooling rate relatively uniform and keep off stresses.

- Avoid internal features – they require additional steps in mold making and may cause problems in metal flow.

- Place parting line near corners – they will hide the flash.

- Use straight parting lines wherever possible – It makes the mold making easier.

- Avoid large flats - large flat areas tend to deflection.

- Machining Allowances - allow excess material for later machining of critical dimensions.

- Use a draft angle - A small angle of 0.5-2° on the vertical walls makes it easier to remove the pattern.

- In the designing of cast shapes, an understanding of finished part dimensional prerequisites is essential to attain near net dimensions at most economical cost. The designers should apply as high a tolerance as possible.

- Fix geometric tolerances, like profile of a surface for complex blended surfaces.

And most important of all, consult and work with your casting manufacturer to improve the performance, effectiveness and quality of your casting designs.

Best Designs of Cast Expo '08

An oil tank for Harley Davidson, developed by the Carley Foundry Inc. in Blaine, MN, was named as the winning product. The product houses and circulates oil across the new Harley Rocker’s operating system, and it is a critical element of the cycle’s cosmetic look. The product was cast in A356-T6 aluminum using semi-permanent molding and weighs 9.25 lbs. In addition to its aesthetically pleasing design, it provides superior heat resistance than the available options — a plastic design and a multi-piece fabrication.

Contech Wins Twice in the International Die Casting Competition'08

A division of Marathon Automotive Group, Contech U.S., won two awards in the 2008 International Die Casting Competition, sponsored by the North American Die Casting Association. It is an annual competition that acknowledges outstanding castings depending on their design, effectiveness, cost savings, ingenuity, innovation, and the potential to change industry trends.

A rear knuckle component for the Jaguar XK8 was named the winner of Aluminum, Squeeze/ Semi-Solid award. It was a large, complex component designed using Contech’s P2000 squeeze casting method. This is the 3rd consecutive year that Contech has won the award in this category, and the 5th time since 2001.

It won the 2nd award under the “Aluminum Die Casting under 1 lb.” category, for a rear-axle thrust rod designed for the BMW X5. Fully designed by Contech, the rod replaced a multiple-part steel assembly and provided about 50 % weight savings for the automaker.

Best in Class Winners

This is a material handling steering / linkage assembly designed by the Piad Precision Casting Corp. The component is a brass permanent-mold chill casting, which replaced a weldment that comprises of ten pre-fabricated pieces, nineteen weld joints, and four bushings.

This is a material handling steering / linkage assembly designed by the Piad Precision Casting Corp. The component is a brass permanent-mold chill casting, which replaced a weldment that comprises of ten pre-fabricated pieces, nineteen weld joints, and four bushings.

Dotson Iron Castings has developed this agri-speed hitch, which is an assembly of austempered ductile iron and ductile-iron green sand castings, which was reverse-engineered from the customer’s weldment. The component has resulted in reduction of 30% in weight and 40% in cost.

This is a 124-lb. white iron no-bake sand casting, designed by the Castalloy Corp. for use as a static mixer tube. Conversion from a 7 piece fabrication, the component eliminates all assembly labor and allows the designers to incorporate strategic thickening of wear areas.

Designed by Denison Industries, this is a main transmission housing for a military contract, transforming a multi-piece assembly into a 200-lb casting. The component is designed using A356-T71 aluminum no-bake sand that eliminates tubing, hydraulic lines, and passageways.

Honorable Mentions:

This is a 21-lb multifunction bracket/towing eye designed for Volvo by Citation Columbiana. Developed using ductile-iron lost-foam casting process, the component eliminates the machining and heat treating required on earlier bracket designs.

This is a 21-lb multifunction bracket/towing eye designed for Volvo by Citation Columbiana. Developed using ductile-iron lost-foam casting process, the component eliminates the machining and heat treating required on earlier bracket designs.

Developed by General Motors & Diversified Machine, this component is a 33.5-lb. vacuum riserless/ pressure riserless casting designed to serve as an engine cradle for the Cadillac CTS. The casting was poured in A356 aluminum and welded to 4 aluminum extrusions to create the engine cradle.

Developed by General Motors & Diversified Machine, this component is a 33.5-lb. vacuum riserless/ pressure riserless casting designed to serve as an engine cradle for the Cadillac CTS. The casting was poured in A356 aluminum and welded to 4 aluminum extrusions to create the engine cradle.

This is an automotive aftermarket intake manifold designed by the Trilore Technologies. The component is a 13-lb. A356-T6 aluminum casting, converted from a plastic molding.

This is an automotive aftermarket intake manifold designed by the Trilore Technologies. The component is a 13-lb. A356-T6 aluminum casting, converted from a plastic molding.

Eck Industries make use of the ablation process to design this 4.9-lb, A356-T6 aluminum rear motorcycle frame. The component provides improved mechanical properties in its thin sections.

Metal Prices Expected to Stay Higher for Longer

The prices of raw materials used in steel making, such as iron ore, coal and scrap metal are expected to keep on rising for many years, keeping pressure on manufacturers and consumers, said the chief of US steel maker Nucor Corp.

The prices of raw materials used in steel making, such as iron ore, coal and scrap metal are expected to keep on rising for many years, keeping pressure on manufacturers and consumers, said the chief of US steel maker Nucor Corp.According to Mr. Dan DiMicco (the chairman, president & CEO of Nucor Corp.), “the bull run for commodities market will continue for decades to come and so the people need to get used to it”.

This can be seen from the market, where iron ore is up several hundred per cent, scrap prices are $600 (U.S.) to $700 per ton, pig iron is $900 per ton, and coal is escalating at an even fast pace. According to Mr. Dan DiMico, “raw materials, including scrap, will continue to see rise in prices”.

Earlier, Mr. John Surma (CEO – U.S. Steel Corp.) told Reuters that “high iron ore costs were pushing steel prices even greater and he warned that increasing demand is limiting miners' capacity to provide raw materials”.

Steel prices have surged around 50 percent this year and this can be attributed to continuously increasing raw material costs and the global demand.

Escalating Scrap

Nucor produces majority of its steel from scrap metal, the cost of which has increases twice than what it was last year and seventy percent more than 3 months ago.

Scrap is the primary feedstock for electric arc furnaces ran by mini-mill steel makers such as Nucor, while structured steel manufacturers such as U.S. Steel Corp. make their products in blast furnaces that use coking coal to melt iron ore.

Recently Nucor has moved to more secure supplies. The Charlotte, North Carolina-based company is the biggest buyer of ferrous scrap in North America with aggregate scrap purchases of 22.8 million tons in 2007.

Earlier this year, the company paid $1.44-billion for scrap processor David J. Joseph Co. and recently acquired the assets of Galamba Metals Group that run 16 scrap-working facilities in Kansas, Missouri and Arkansas, and Metal Recycling Services Inc., established in Monroe, North Carolina.

According to Mr. DiMicco, the future looks bright for steel industry with increasing global demand, especially from China, India and other emerging economies. He compared the situation with that of the late 1940s and early '50s, when the industry was being reconstructed after the destruction of World War II.

5 Ways to Improve Die Performance

The 5 key factors, which can extend die life are -

- Die Design

- Die Material

- Heat Treatment

- Coatings

- Operation / Maintenance

Judging Die Performance

In general, improved die performance results in more parts at a lesser cost. The 3 factors, which affect the tooling and limit the die performance are -

- Soldering and chemical attack between the die material and liquid metal.

- Wear & erosion.

- Heat checking or thermal fatigue occurring as a result of the thermal cycling, which takes place with each shot or casting cycle.

Performance Improvement Ways -

The 5 key factors given here for the improvement of die performance are a beginning point for determining what combination of elements will have the highest impact on performance in a specific situation. As like there are several nuances within each performance improvement element, the particular steps, which will produce the best results will depend upon various factors, such as the die casting type (hot or cold chamber), the cast alloy, size of shot, or the wall of casting (thin wall or thick wall).

Die Design

For the improvement of tool life, the parts should always be designed with round edges or generous radii. Gate location is also a critical factor, as the control of metal flow in die cavity is a major factor in producing sound die castings. The metal must necessarily flow quickly and uniformly into the die, as it minimizes the sharp direction changes, which can result in premature tool wear.

Die Material

For majority of tool construction, casters generally prefer superior grade H13 tool steel as the starting point. However, many die casters nowadays, are realizing that the die life can be significantly improved by using modified versions of H11 steel, heat treated to a hardness level of 48 HRC. H11 has greater molybdenum content, with lower vanadium and silicon, facilitating greater toughness than H13, superior temper resistance, which improves the die life in demanding applications, such as - thick-walled castings.

Heat Treatment

Research have proved that heat treatment process is as critical in impacting the die life as the selection of the proper die steel. The thermal fatigue cracking can be greatly reduced by using an austenitizing temperature, which will place the optimum amount of carbide forming elements in solid solution in the austenite. When combined with a speedy quench rate, the toughness remains unaffected.

Coatings

Coating and/or surface treatment helps in improving the tool life by preventing the soldering and erosion between the tool steel and the liquid alloy being cast. Though surface modification techniques like ferritic nitrocarburizing and plasma ion nitriding also improve the die life, coatings generally provide better improvement.

Operations/Maintenance

As good design is the starting point in ensuring the long die life, proper operation and maintenance are critical to the overall success in improving the die performance. These include the die set up procedure, pre-heating tools and verifying clamping pressures. In case, a hard coating has been applied, the cleaning pressure needs to be changed to avoid damaging the coating.

The Role of Associations & Groups in Metal Casting Industry

surgical equipment, and is critical to the modern human life.

The Need for Industry Associations & Groups

Although metal casting is integral to manufacturing industry, it had not undergone any development for a very long period of time. The basic need for the formation of metal casting related associations was to address the needs of the industry and to develop the processes and techniques of casting. Some of the associations and groups formed by the companies are constantly dealing to make such proposed reforms and discuss the various problems and issues faced by the industry. Many of them have also come up with profound technical rectifications and several new proposals.

Aims & Objectives

Over the years, the basic aims and objectives of metal casting industry associations and groups have remain unchanged. Some of the important objectives of associations working for the metal casting industry are -

- Continuously work for the development of more refined metal casting techniques and processes.

- Help the member companies to improve their quality standards in this ever demanding industry.

- Work for the spread of appropriate technology.

- Work for the development of new innovations and inventions for the technological benefit of member companies.

- Help the member companies to cut their production costs and improve productivity.

- Address the different issues and problems, the industry is facing.

Companies working in the metal casting industry are often pressurized and accused for polluting the environment. Metal casting industry associations and groups are working in this area to help the member companies in proper disposal of pollutants. For instance, some of the associations have persuade the companies with operations close to each other to setup a common facility for the disposal of harmful pollutants. Many of the associations have setup their own norms and practices for member companies in this regard.

Safety of Manpower & Environment

It is also an important duty of associations to keep a tab on the safety of workers. The industry being a dangerous place to work in, the associations have dictated several safety norms to the member companies. These norms are also important from the point of view of avoiding any trouble or intervention from the Government.

Spreading Awareness

It is an important duty of industry associations to make the member companies and people aware of ongoing developments and research in the field of metal casting. The associations arrange international expos and exhibitions for the spread of knowledge. The associations also stand for their member companies in various seminars organized at the international level.

Commercial Aspects

The metal casting associations also function as exchange houses for commercial meetings. Many associations also help the member companies in understanding the market conditions and the ways to improve their profitability and financial stability.

Some of the important associations and groups working in the metal casting industry are -

- Casting Industry Suppliers Association

- Indiana Cast Metals Association

- Institute of Scrap Recycling Industries

- American Foundry Society

- California Cast Metals Association (CCMA)

- Forging Industry Association

- North American Die Casting Association

- American Extruders Council

- Cast Iron Soil Pipe Institute

- Steel Founders Society of America

- Minerals, Metals & Materials Society (TMS)

Increased Competition – Forcing the Foundries to Reduce Running Costs

During the last decade or so, foundries are facing a big challenge to survive and stay in the business. Companies are striving to find an ever cheaper manufacturing base and are trying to buy the consumables products they require to operate their business as economically as possible.

During the last decade or so, foundries are facing a big challenge to survive and stay in the business. Companies are striving to find an ever cheaper manufacturing base and are trying to buy the consumables products they require to operate their business as economically as possible.As the customers are looking to buy at ever lower costs, the crucible business is becoming tougher day by day.

Some companies are adopting innovative approaches to tackle this problem. They are working on methods and practices to optimize the life time of their products. Some of the highlights of findings are -

- Long and stable service life of products

- Good conductivity of crucible over the use period

- Protection glaze, which can withstand the longer time in use

- Isostaically pressed to give an even and consistent material structure

Companies, such as Mammut-Wetro have successfully taken up these challenges to reduce their running costs. Mammut-Wetro has a long experience of foundry industry with a technical team that has an extensive knowledge of ceramics and all this is backed by a highly sophisticated laboratory that has facilitated the testing and proving of ideas to attain the desired results.

Mazak Ltd. of Bloxwich, Walsall has been working with the products for many years now, the biggest zinc alloy plant in the UK, using two ton and one ton capacity crucibles. During this period, the company has achieved highly stable operating conditions. The structural unity of the crucibles is maintained even after the complete service life, ensuring the safe and easy removal of a used crucible. According to Keith Sargeant, the Works Director of Striko, Their main advantage has been the consistent quality of products supplied by Striko UK Ltd.

Improving Energy Efficiency

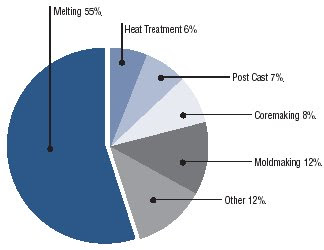

The most energy-intensive process in metal casting is melting. Companies are working on methods and practices to improve melting efficiency as well as to improve yield, thereby reducing the amount of metal that must be melted and hence the production cost.

How to measure success?

- Increased yield and reduced scrap — By improving the yield and reducing scrap, the amount of metal that must be melted decreases and in turn saves energy.

- Melting efficiency - Melting represents 55% of the cost of process energy. Improvement in melting efficiency helps save energy and reduce production costs.